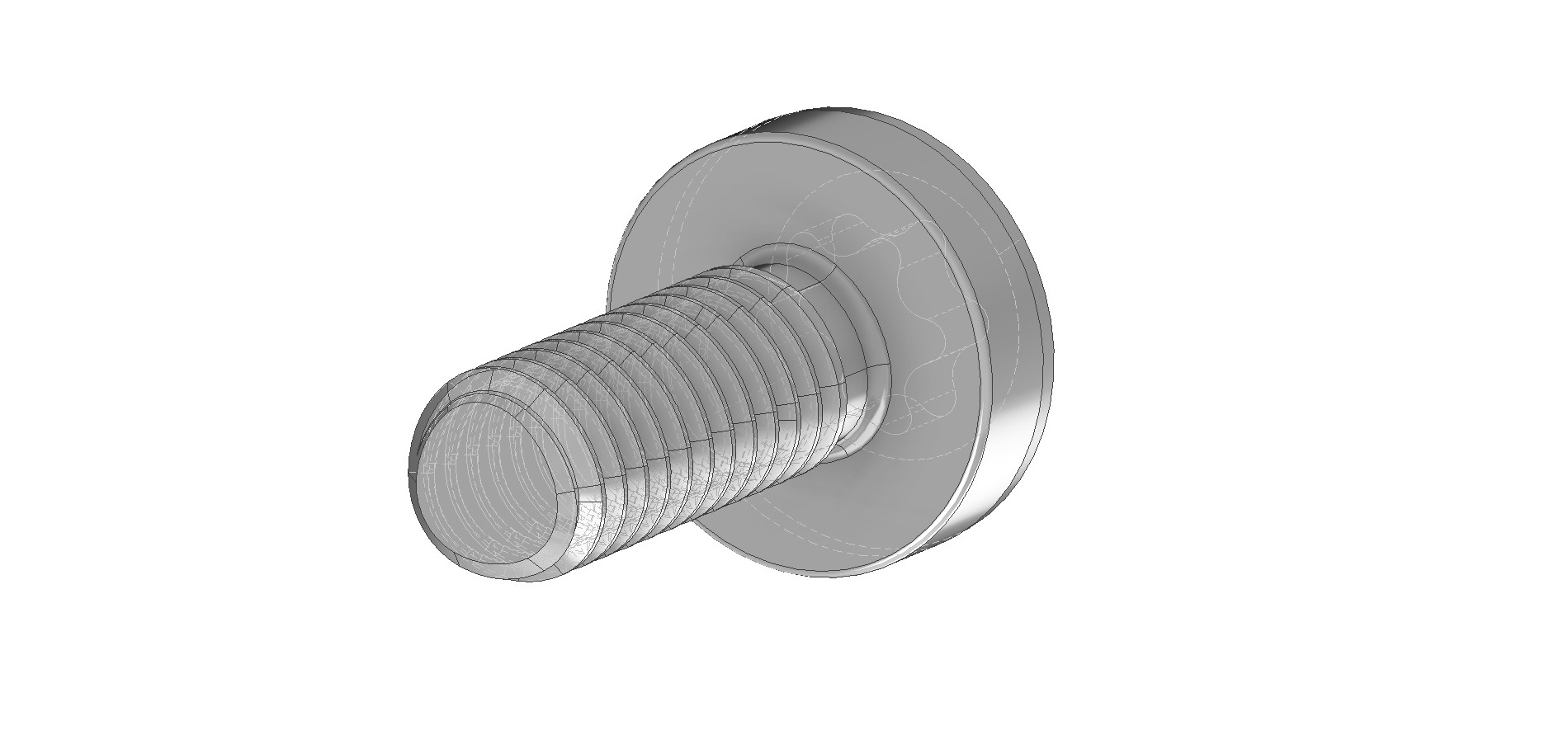

WR®-TriTite 300

A new developed WR® screw solution for usage in metal material

A thread rolling trilobular configuration forms thread in drilled, punched or cored holes in metal material. Due to the self threaded shank the resistance to vibration loosening is improved.

The application of our WR®-TriTite® reduces your assembling costs and expensive tapping operations are not longer necessary.

The trilobular shape reduces friction and the driving torque.

Benefits:

- Trilobular configuration

- 60° thread angle

- Resist vibration loosening

- Removal of inefficient operations

- Chipless metal forming

- Consistent thread profile

- Generates strong mating thread

- Maintains joint integrity

- Lower driving torque

- Improves assembly operations

- Easy replacement with machine screws

- Removal and reinsertion of fasteners are possible

- Material:

- Steel: grade 10.9 or acc. to DIN ISO 7500

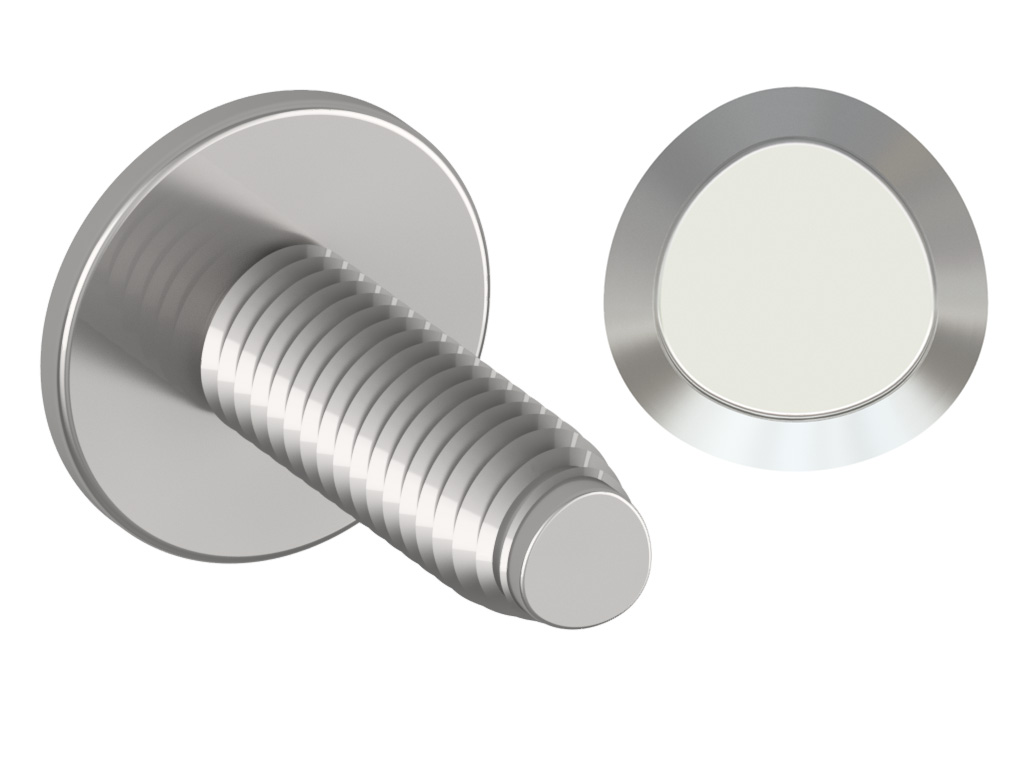

Alternative thread geometry

WSH-Spiralform®

A thread-rolling configuration developed for a sure and easy screw connection in metal material.

Benefits:

- Metric ISO standard thread DIN 13 6h

- 60° thread angle

- 4 small lobes positioned at 90° around the diameter

- Forms easily the internal thread

- Optimum contact between screw thread and mating materials

- Lubrication for a better friction

- Acc. to DIN 7500 / DIN EN ISO 7085

- Material:

- Steel: grade 10.9 or acc. to DIN ISO 7500